Ocean Applied 's LTMS Liquid Transmission System

Product Details

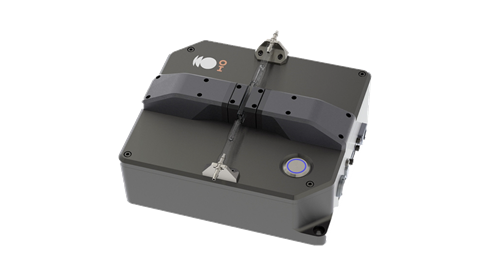

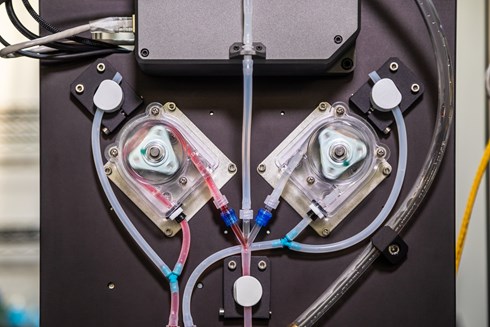

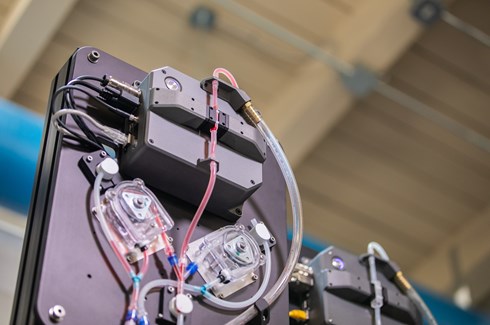

Ensure Color Consistency for Your Customers with Ocean Applied's LTMS Liquid Transmission System. The LTMS is a spectroscopy-based system for real-time, in-line monitoring of liquids — including pharmaceuticals, industrial dyes, plating baths, and chemical coatings. It’s based on the use of a built-in, flow-cell setup with automatic fluid handling. The sensor portion of the LTMS is a compact transmission- and absorbance-platform with a rugged, benchtop configuration designed for harsh environments and industries — including consumer electronics manufacturing, food and beverages, and semiconductors.

The LTMS is a powerful tool for managing batch-to-batch color consistency in plating baths for metal parts or dye baths for textiles. It’s also primarily used for monitoring concentration-levels for chemical coatings and pharmaceuticals. Plus, as an in-line system, the LTMS eliminates the need to transport samples from the production-line to quality-control labs — saving time, resources, and making it possible to quickly address any quality issues in real time.

Product Overview

- Fully integrated system – robust, customized system complete with spectroscopy-based transmission measurement, modeling algorithms, and fluid handling

- In-line, batch-to-batch color consistency and concentration monitoring – real-time measurements speed up workflows by detecting quality issues as they occur

- Maximized production yields – improve batch efficiency by minimizing rework and increasing uptime

- Flexible setup – as measurement needs change, you can easily move LTMS from tank to tank to analyze new liquid samples

- No specialist needed – can be operated by manufacturing personnel

LTMS Specifications

| Wavelength Range | 400 – 700 nm (UV model available) |

| Optical Resolution | 1.0 nm |

| Signal to noise ratio (typical) | 8000:1 (using 100 measurements over 600 sec) |

| Cycle Time | 40 ms to 5 min. (depending on sample absorbance, path length, and SNR requirements) |

| Communication | TCP/IP, RS-232, RS-485, ModBUS RTU to PLC |

| Sample Interface | Flow cell (multiple path lengths available), cuvette holder, custom interfaces upon request |

| Output | Transmission/absorbance values, answers through machine learning models (e.g., concentrations, pass/fail) |

| Dimensions | Control Unit: 180 x 160 x 100 mm (7.1 x 6.3 x 3.9 in.)w/ Fluid System: 980 x 410 x 460 mm (38.6 x 16.2 x 18.1 in.) |

| Weight |

Control Unit: 4.0 kg, 8.8 lbs w/ Fluid System: 33 kg, 73 lbs |

Downloads

application note

product sheet

user guide

Additional Information

LTMS: Liquid Transmission Measurement System

In this video, we’ll demonstrate the LTMS System — a robust platform for real-time, in-line monitoring of color consistency and liquid concentration levels.

Industries

Click on this link that will take you to a roundtable discussion. You’ll hear our experts describe the basics of color, differences in emissive and reflective color measurements, and color applications that transcend aesthetic considerations.

To improve product quality and streamline processes, manufacturers are constantly seeking more effective methods of in-line color monitoring. In this application note, we discuss a versatile spectral system for non-contact color measurements.

Learn more about the LTMS in the Physics World Magazine article ‘In-line Spectral Monitoring Gets Ready To Shine.’ Just follow the links to read excerpts from the full article.