Making Measurements

A good place to start your reflectance measurements in OceanView operating software is with the Reflectance Wizard. Follow the prompts to ensure good measurement practices and optimized settings. Here are some additional recommendations:

- Remember to warm up the light source 15-20 minutes before taking measurements.

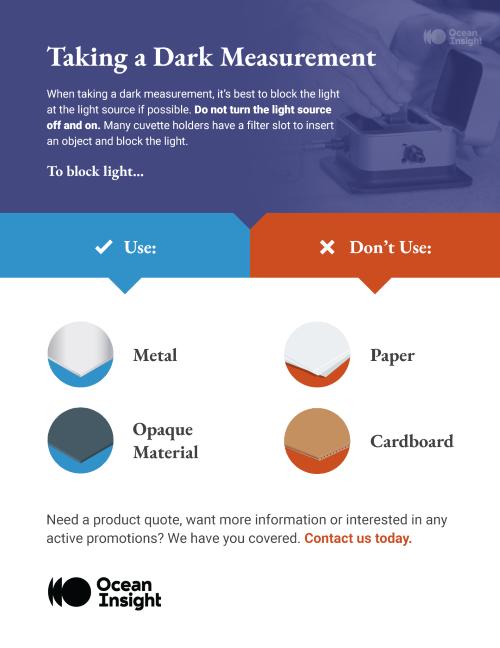

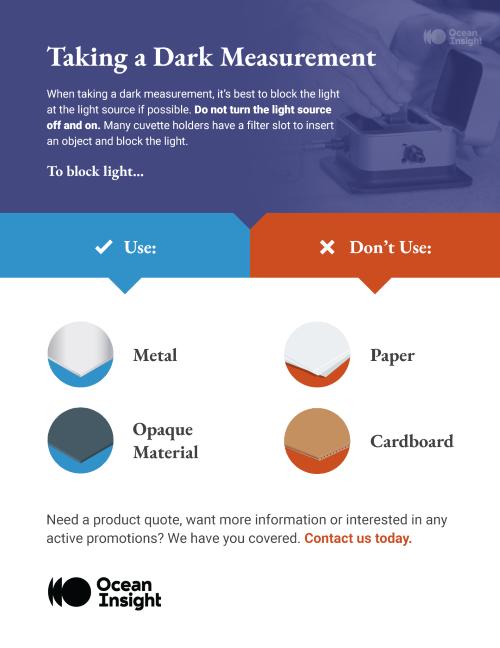

- Never turn off the light source to take a dark measurement. Use the built-in light source shutter or point your sampling optic into a dark place instead.

- Be sure to maintain consistent sampling geometry in your setup – i.e., keep the angle and distance from the probe or sphere to the reference and sample the same from measurement to measurement.

- Especially with lengthier or more involved measurements, take frequent dark and reference measurements to reestablish an accurate baseline.

- Set the integration time so that your reference reaches 80% to 90% of the full scale of the y-axis. (The Reflectance Wizard will do this for you.) This allows you to take advantage of the full dynamic range of the spectrometer, improving signal to noise (S:N) performance.

- Use scans to average to improve signal-to-noise. The S:N improves with the square root of the number of averages taken. For example, setting averages = 9 improves the S:N by a factor of 3.

- Increasing the boxcar value can also smooth out noise in the spectrum. It is a moving average with wavelength. If this value is set too high, it will begin to blur the spectral shape, so use this feature carefully. To smooth data without affecting resolution, set the boxcar value equal to the pixel resolution of your spectrometer.

- Use the nonlinearity correction. The non-linearity correction compensates for the non-linearity effects of the detector, which occur above 80% of the saturation level. Non-linearity correction improves the accuracy of the spectral shape.

- Consider electrical dark correction (EDC). Dark current levels tend to vary slightly over time due to temperature variations, and the EDC option will keep the offset dark levels stable for a longer period. In OceanView software, EDC is automatically enabled for spectrometers that support it, and is required to enable linearity correction. The user can disable EDC, if needed.

For spectrometers that don't have the dark pixels required for EDC, the EDC control is replaced by the option to Store a Dark, which is managed by the user through the Acquisition Control Panel. The first step in the OceanView Wizards is to set your acquisition parameters, so the user can enable EDC then as well.

- Use optical filters between the sampling optic and spectrometer in applications where blocking or balancing certain wavelengths of light is desirable.

Light Sources

- Warm up the light source 15-20 minutes, as its output will change very slightly until it reaches thermal equilibrium.

- Never turn off the light source to take a dark measurement. If your light source has a built-in shutter, use this instead. Alternatively, you can point the illuminated probe or opening of the integrating sphere into a dark space to take the dark measurement so that no light scatters back in. A dark measurement taken this way is more accurate because it includes any scattered reference light that will be present in the sample measurements, allowing that light to be subtracted properly.

Resist the urge to point the sampling optic at something black (like a piece of paper or a cover cloth) for your dark measurement. Even objects that appear to absorb all wavelengths usually reflect some colors better than others.

Reflectance Standards

When is a “standard” not a standard? When it’s a WS-1 series diffuse reflectance standard. That’s because WS-1s result in relative measurements. The important thing to remember is that a standard is only absolute if it comes with calibrated values. The WS-1 and WS-1-SL are diffuse reflectors, like most surfaces we encounter every day. Their absolute reflectivity, therefore, depend on what range of angles of reflected light are collected from them.

The only guarantee from the WS-1 or WS-1-SL is that it will be nearly equally reflective at all wavelengths, regardless of the angle of collection. That property makes either reflectance standard a versatile option for use with any sampling optic. When a WS-1 or WS-1-SL is used as the standard in a reflectance measurement, OceanView essentially defines its reflectivity as 100%. The relative reflectivity spectrum is accurate in shape, if not in amplitude, which is acceptable for most purposes (including color measurements). This is why we recommend using the Non-Unity Correction feature in OceanView to get the true reflectivity as a function of wavelength.

On a different note, there are times in the field when lose your reference standard or it gets so dirty or damaged that there is no hope of a salvageable reference measurement. When this happens, you may be tempted to use a white sheet of paper as your reference, but don’t. Paper is not as spectrally “white” as it appears (measure a piece sometime).

A piece of Styrofoam™ will work much better. It provides diffuse reflection and has relatively even reflectivity across the visible range. Just be sure to take that piece of Styrofoam back to the lab with you so that you can measure it against a proper reference standard and correct all your spectra accordingly!

Sampling Optics

- When using a reflection probe for specular (90°) measurements, the diameter of the sample area being measured is equal to ~½ of the distance, d, between the end of the probe and the sample. At 45° angle of incidence, it becomes an oval that is 0.44d by 0.63d.

To see exactly where the reflection probe is reading light from the sample, attach the read fiber to the light source temporarily. The spot illuminated on the sample is exactly where that read fiber is “looking.” If you’re using the RPH-1 probe holder, turn the holder over and place a piece of paper on the contact surface to see the spot size illuminated through the paper.

- To measure granular samples using a reflection probe, we recommend our angled probe, which has a 30° angled window to reduce specular effects. Our standard reflection probe positioned at 45° in the RPH-1 probe holder is another option.

If you're measuring a homogeneous sample like some powders, combining a standard reflection probe with a petri dish and illuminating from below creates a flat sample surface at a consistent working distance from the reflection probe. A flat sample surface will give more consistent results with similar baselines as compared to reflecting off the uneven upper surface of the sample.

Fill the petri dish with the sample powder or dense liquid, then point the reflection probe up at the petri dish from below. When no light can be seen coming through the sample from above, there is enough material present to ensure consistent measurements from one sample to another.

To take a reference measurement, put the reference standard face down on the petri dish, being careful to keep the reference clean. This type of measurement is best done in a darkened lab to prevent variations in ambient light from influencing the data.

Another option for measuring granular or irregularly shaped samples is the DR-Probe, a 45-degree diffuse reflectance probe with integrated tungsten halogen light source.

- When using an integrating sphere for color measurements, we recommend avoiding use of the gloss trap feature, which is available on the ISP-50-8-R-GT model. The gloss trap tends to decrease the value of L* considerably for dark colors. A glossy sample looks darker to the eye than a matte or textured sample, even if it has the same pigmentation. People instinctively position glossy objects like magazines so that the gloss component doesn’t enter the eye, and a gloss trap simulates that.

However, for medium to low gloss samples, using the gloss trap doesn’t completely exclude the specular component. Including the specular light for these samples will give better consistency in the values measured from one instrument to another. For textured samples with some gloss component, the best geometry is one that minimizes the surface effects.