Subscribe to Our Blog

Receive updates from our team as we share application notes, customer spotlights, educational tools, spectroscopy how-to’s, and more.

As the world moves from standardized medicine to greater personalization, and from outmoded methods for responding to public health crises to faster, more cohesive protocols, the need for non-invasive technologies to diagnose, monitor and treat medical conditions continues to grow.

IMPORTANT: PLEASE REFRESH YOUR BROWSER IF YOU DO NOT SEE ANY IMAGES/SCREENSHOTS/SPECTRA ON THE PAGE.

Spectral technologies are evolving to help medical researchers and device developers meet changing patient demands with solutions that are simpler, smarter and more robust than ever.

When the miniaturization of spectral technologies began in the late 1990s, those early instruments benefited from a perfect storm of technological circumstances: the development of imaging detectors for mass-volume markets, which lowered system costs and allowed designers to shrink the instrument footprint; the evolution of personal computers, which enabled spectrometers to process high-speed spectral data; and the growth of fiber optics, which made it easier to bring the spectrometer to the sample.

These developments have benefited scientific, research and industrial sectors and spurred additional advances in spectrometer development. Successive generations of miniature spectrometers have become faster, more accurate and more compatible with data transmission communication protocols including Ethernet and Wi-Fi. This has virtually eliminated performance trade-offs inherent to earlier miniature spectrometers and makes them more scalable for OEMs and other high-volume users.

In biomedical and life sciences applications, spectrometers are routinely integrated into other devices, combined with fiber optic components for use as subassemblies, or designed into fully realized instruments for applications ranging from biofluidics control to molecular diagnostics. Here are two more examples:

A leading medical device manufacturer recently assessed the use of spectroscopy as part of its quality control for antimicrobial-impregnated catheters. To help prevent biofilm formation and subsequent infection, the company coats its implantable catheter tubes with a polymer solution containing a suspended antimicrobial agent. This coating is then cured.

To ensure that minimum antimicrobial concentrations are present and the coating applied uniformly, a liquefied sample of the cured antimicrobial layer is sent to an outside lab for HPLC quantification. This process is time-consuming, expensive, destructive to the product and does not guarantee a uniform layer. The manufacturer needed an onsite system that could measure the concentration and coating uniformity quickly, accurately and with no sample destruction.

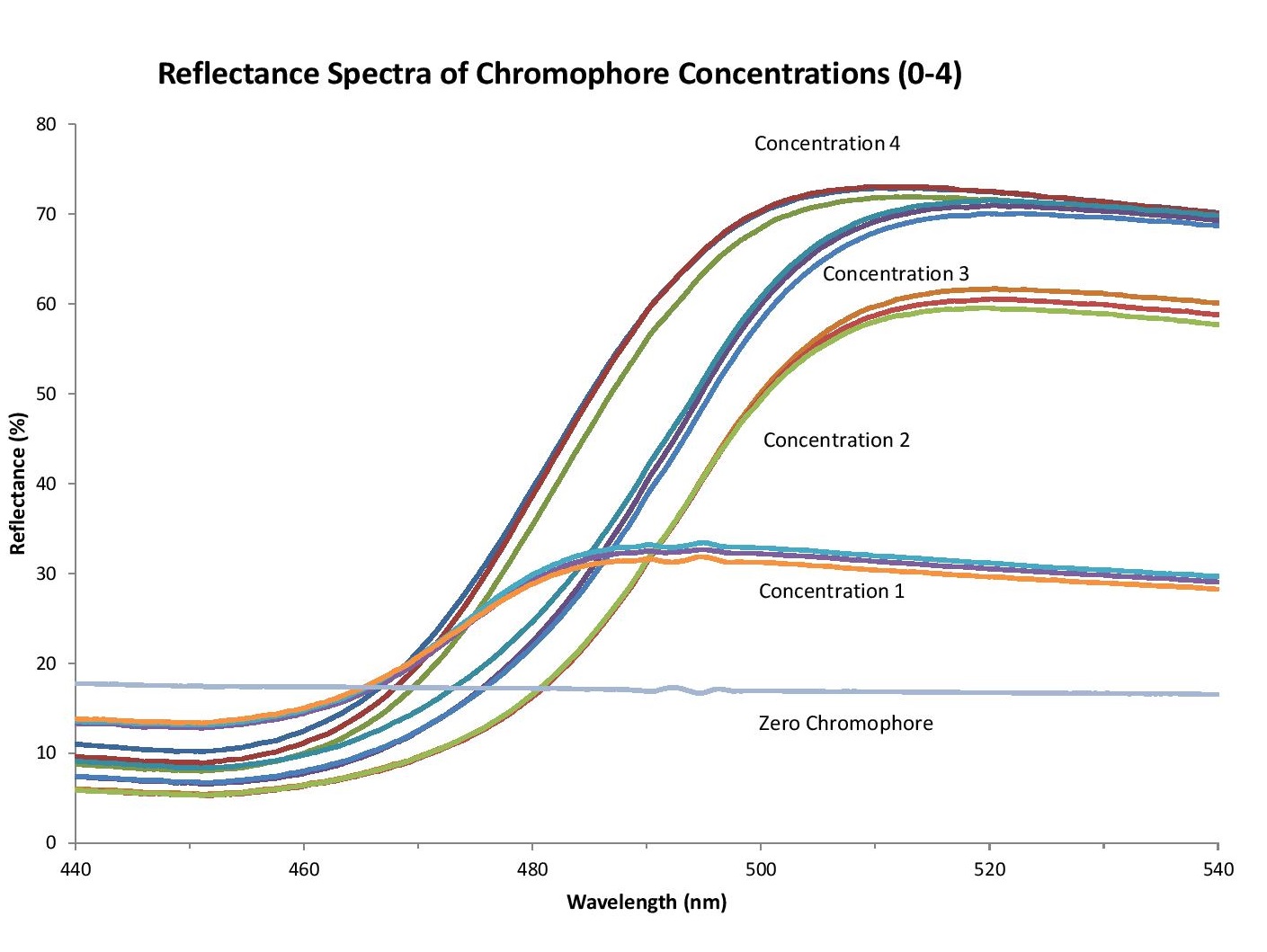

To measure antimicrobial concentrations, a high-sensitivity Ocean HDX miniature spectrometer was combined with a high-power tungsten halogen lamp and reflection probe mounted in a ring stand for repeatability. The average of each concentration spectra was taken and then divided by a clear reference sample spectrum. This resulted in the average relative reflectance of each concentration (Figure 1). These values plotted against the HPLC concentration data revealed an R2 correlation value of 0.9924. The striking correlation between relative reflectance of a miniature UV-Visible spectrometer and the HPLC-determined concentrations empowered the manufacturer to implement this setup into its quality control process.

Figure 1. An Ocean Optics miniature spectrometer (350-925 nm) measures the reflection of coatings used on antimicrobial-impregnated catheters. Repeatable coating concentration and uniformity results ensure catheter integrity.

Biological tests and processes have seen a recent burst in attention from new technologies hitting the mainstream, such as rapid virus detection, custom-engineered medical treatments, and at-home genetic tests. In many of these tests, UV absorbance is used to determine the concentration of a constituent.

Depending on the sample and application, UV protein detection may be necessary at very low limits or at extremely thick concentrations. The power to perform accurate measurements at both extremes is available via high-sensitivity miniature spectrometers, which provide excellent resolution at normal light levels as well as stable, meaningful readings at the lowest intensities.

As testing demonstrates, a miniature spectrometer can successfully generate a standard curve for bovine serum albumin (BSA). BSA is a protein derived from cows that is frequently used for biochemical applications.

Why is this important? The generation of a standard curve (also known as a calibration curve) is a typical procedure in many biomedical, diagnostic and life science research laboratories. An accurate determination of protein concentration is the first step in assays involving proteins. With high performance, newer model miniature spectrometers, researchers and developers have a flexible set of tools for UV absorbance measurements including those required for determining the concentration of an unknown protein.

Pushing the frontiers of what’s possible in understanding disease, developing diagnostics, and using biotechnology to advance therapies demands a versatile toolkit of analytical instruments and the guidance of knowledgeable partners.

Today’s miniature modular spectrometers, both customizable and flexible, are ideal for supporting the application of spectroscopy techniques to biomedical research and diagnostic device testing and development.

Preconfigured Ocean HDX Spectrometers

Options available

UV-Visible Reflection/Backscatter Probes

Prices From $713.00

In this article, we describe how a catheter manufacturer has traded HPLC for onsite reflectance spectroscopy to streamline its antimicrobial coating quality processes.

In this application note, we use an Ocean HDX spectrometer to generate a standard curve for bovine serum albumin (BSA).

Spectral reflectance offers an objective way to measure skin throughout dermatological studies, providing quantitative data on color and absorbance. To demonstrate, we simulated models for melanin and moisture in skin, then measured several samples.

Receive updates from our team as we share application notes, customer spotlights, educational tools, spectroscopy how-to’s, and more.